Inside Apple's Supply Chain: How Are iPhones Really Made?

- Your iPhone isn't just from one place—it's a global puzzle.

- China is a huge part of it, but Japan, the USA, and India all have hands in the magic.

- From rare earths to glass, every country has its own important part to play.

- Read on to get an inside look into how the Apple iPhone is made.

Few products in the world command as much attention as the iPhone. With over 230 million units shipped annually, Apple’s flagship smartphone dominates markets worldwide. But behind the sleek glass and powerful chip lies a complex global supply chain—a network of parts, suppliers, and assembly lines scattered across continents.

The iPhone's creation isn’t a simple “Made in China” story. Instead, it’s the result of meticulous collaboration between countries—each contributing critical pieces to the puzzle.

Components from Around the World

- Japan and Korea: The iPhone’s display—arguably its most defining feature—comes from giants like Samsung and LG in South Korea. Meanwhile, Japan plays a pivotal role by supplying flash memory and DRAM from Kioxia and Sony.

- USA: Many of the iPhone’s core innovations originate in the U.S. The A18 and A18 Pro chips, for example, are designed in Apple’s Cupertino headquarters. However, while the design is American, the manufacturing is handled by TSMC in Taiwan. Other key parts, like Corning's Gorilla Glass, may come from their factories in Kentucky or abroad.

- Europe: While Asia often gets the spotlight, Europe is far from sidelined in Apple’s manufacturing process. The gyroscope, which helps the iPhone track orientation, is produced by STMicroelectronics in Switzerland. As Europe’s largest semiconductor manufacturer, STMicroelectronics plays a critical role in Apple’s supply chain, despite the dominance of Asian suppliers.

- China: China remains the assembly powerhouse for the iPhone. In addition to assembly, China supplies key materials like rare earth minerals, which are essential for producing components such as the color display, speakers, and vibration units. These minerals are primarily sourced from regions like Mongolia, giving China a crucial role in the iPhone’s production.

- India: While China dominates assembly, India is becoming an increasingly important player in Apple’s supply chain. With rising geopolitical tensions and Apple's desire to diversify away from China, the company has steadily increased its investment in India, where iPhones are now being assembled at Foxconn’s plant in Tamil Nadu. This shift not only reduces dependency on China but also helps Apple tap into India's growing market.

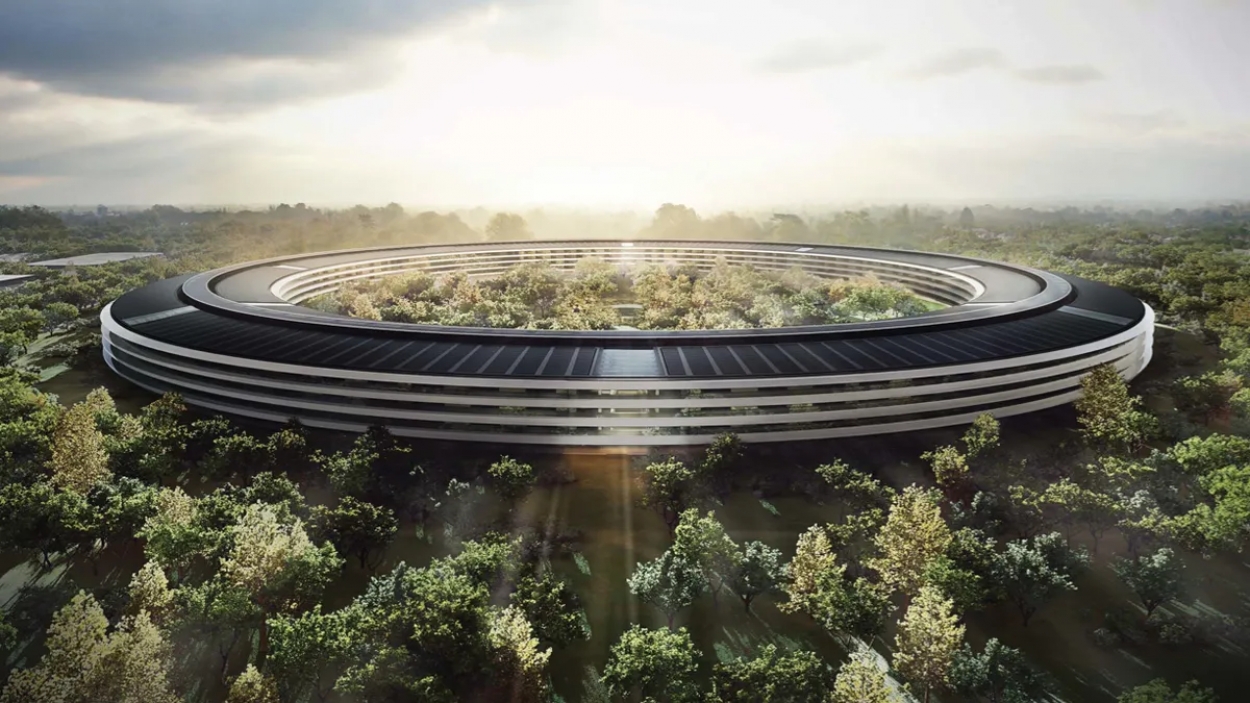

Photo via CNET // While most of the iPhone is manufactured and assembled overseas, the design of much of the hardware and components is actually done in-house at Apple's Cupertino headquarters.

Photo via CNET // While most of the iPhone is manufactured and assembled overseas, the design of much of the hardware and components is actually done in-house at Apple's Cupertino headquarters.

Photo via Apple Inc. // Current Apple CEO Tim Cook speaks with a lineworker at one of their Foxconn iPhone manufacturing plants in China.

Photo via Apple Inc. // Current Apple CEO Tim Cook speaks with a lineworker at one of their Foxconn iPhone manufacturing plants in China.

Assembling the iPhone in China: The World’s Factory

While the iPhone's parts come from all over the world, they converge in China, where companies like Foxconn assemble the device at breakneck speed. But why China? It’s not just about cheap labor, as some might think—it’s about scale.

Photo via EuroNews // Apple is notoriously strict about photos of their products being manufactured. But here, we can see a PC being built in a nearby facility. Insiders say this setup is indeed very similar to Apple's manufacturing processes in China.

China can mobilize thousands of engineers and workers within weeks to meet any last-minute production demands, something no other country can match. A single production line in a Foxconn factory can churn out 72,000 iPhone backplates daily, with some factories running four or five production lines at once. It’s this scale that makes China indispensable to Apple.

Photo via EuroNews // Apple is notoriously strict about photos of their products being manufactured. But here, we can see a PC being built in a nearby facility. Insiders say this setup is indeed very similar to Apple's manufacturing processes in China.

China can mobilize thousands of engineers and workers within weeks to meet any last-minute production demands, something no other country can match. A single production line in a Foxconn factory can churn out 72,000 iPhone backplates daily, with some factories running four or five production lines at once. It’s this scale that makes China indispensable to Apple.

Photo via EJET Sourcing // Tens of thousands of workers work around the clock to pump out iPhones literally 24/7.

Former Apple CEO Steve Jobs once told President Obama, "Those jobs aren’t coming back." The flexibility and speed of China’s manufacturing network make it the only place where Apple’s demand can be met with such precision and efficiency.

Photo via EJET Sourcing // Tens of thousands of workers work around the clock to pump out iPhones literally 24/7.

Former Apple CEO Steve Jobs once told President Obama, "Those jobs aren’t coming back." The flexibility and speed of China’s manufacturing network make it the only place where Apple’s demand can be met with such precision and efficiency.

But that's not the end of the story when it comes to Apple's relationship with China.

To do this story justice, we need to talk a bit more about Foxconn.

What you need to know is that behind the precision and speed of iPhone production is a workforce subjected to intense pressure. Many of Foxconn’s workers, who live on-site in vast dormitories, often endure long hours, with some shifts stretching over 12 hours a day. As the world's largest manufacturer of electronics, Foxconn has so much scale that some cities in China are referred to as "iPhone Cities."

While wages for workers have increased over the years, especially after reports of worker suicides in 2010 prompted Apple and Foxconn to improve conditions, the pace and expectations remain relentless. Workers have reported mental and physical exhaustion, and while the production lines never stop, the human element of this intricate machine shows the toll that such a massive operation can take on individual people.

In response to global criticism, Apple has taken steps to improve working conditions in its supply chain. The company publishes an annual Supplier Responsibility Report and has committed to audits that ensure its suppliers comply with standards for safety, labor, and environmental practices.

Rare Earth Minerals: A Critical Supply Chain Link

While many might think of the iPhone as a marvel of American ingenuity, it’s deeply reliant on rare earth minerals from China. These minerals—such as lanthanides, scandium, and yttrium (yes, yttrium is a real thing)—are crucial for making components like screens and speakers.

China controls around 90% of the world’s supply of rare earth minerals, much of it mined in Mongolia. As the global demand for tech increases, so does the reliance on these raw materials, making China’s grip on rare earths a critical issue for companies like Apple.

Photo via Quartz // A rare earth mineral mine in Mongolia, China.

Photo via Quartz // A rare earth mineral mine in Mongolia, China.

The Price of Efficiency

While Apple’s supply chain is a marvel of efficiency, it’s not without controversy. In recent years, Apple, like many tech companies, has faced criticism over its reliance on unethical mining practices, forcing the tech giant to tighten its supplier standards.

Photo via Globe and Mail // Yes, this is a real photo of what cobalt mining looks like in the Congo. It may seem like an edge case, but actually, most cobalt is mined using very rudimentary tools, equipment and safety standards.

Photo via Globe and Mail // Yes, this is a real photo of what cobalt mining looks like in the Congo. It may seem like an edge case, but actually, most cobalt is mined using very rudimentary tools, equipment and safety standards.

Cobalt, which is a key component in the lithium-ion batteries that power iPhones and other devices, has come under particular scrutiny. About 70% of the world’s cobalt is mined in the Democratic Republic of Congo (DRC), where working conditions are dire. Many of the mines in the region rely on artisanal miners—men, women, and even children who dig by hand, often without basic safety equipment. Reports from organizations like Amnesty International have documented cases of child labor and dangerous working conditions, with miners facing frequent tunnel collapses, toxic exposure, and exploitative wages. While cobalt is essential for modern electronics, its human cost reveals the darker side of the tech industry’s relentless demand for materials.

The Takeaway

The iPhone perfectly illustrates how modern manufacturing depends on international collaboration. It shows that iPhone is more than just a product of American innovation—it’s a global symbol of economic cooperation and interdependence.

It's also good to know that Apple's supplier responsibility audits have led to better oversight of factories, reduced working hours, and initiatives aimed at worker education and health. However, despite these improvements, challenges remain, especially when production demands spike during the release of new iPhone models.

So, the next time you hold an iPhone, remember that you’re not just holding an American invention. You’re holding a product crafted from the hard work and dedication of many different people from the U.S., to Japan, Korea, India, Switzerland, and of course, workers in the massive factories of China.

Recommended by the editors:

Thank you for visiting Apple Scoop! As a dedicated independent news organization, we strive to deliver the latest updates and in-depth journalism on everything Apple. Have insights or thoughts to share? Drop a comment below—our team actively engages with and responds to our community. Return to the home page.Published to Apple Scoop on 22nd September, 2024.

No password required

A confirmation request will be delivered to the email address you provide. Once confirmed, your comment will be published. It's as simple as two clicks.

Your email address will not be published publicly. Additionally, we will not send you marketing emails unless you opt-in.